The new designs incorporate cluster management technology, whereas the LEDs are fixed onto PCB boards forming clusters which are then welded together and extruded in a food grade silicone to form the actual strip lighting, these PCB boards are connected in parallel with the electrical circuit working together in synergy as a lighting platform, but independently in the unlikely case of failure, this means if there is a failure on any components of the lighting it would be isolated and not affect the remaining lighting system.

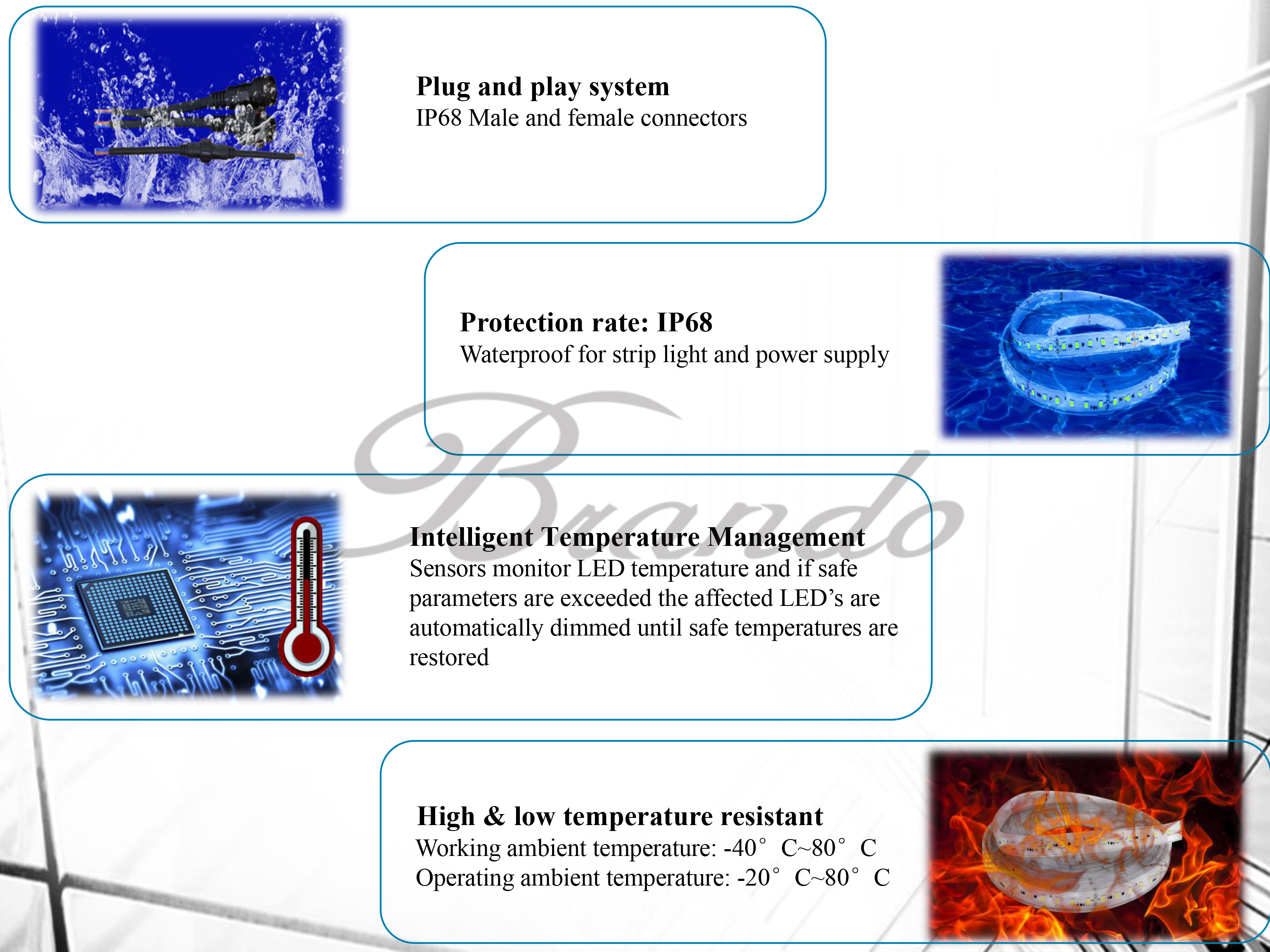

Plug and play system

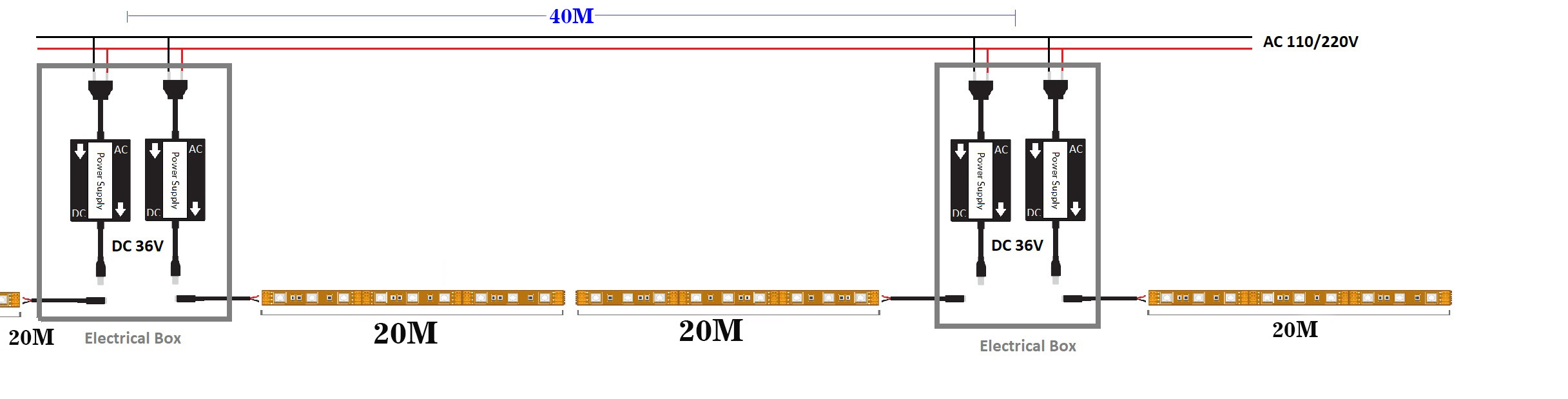

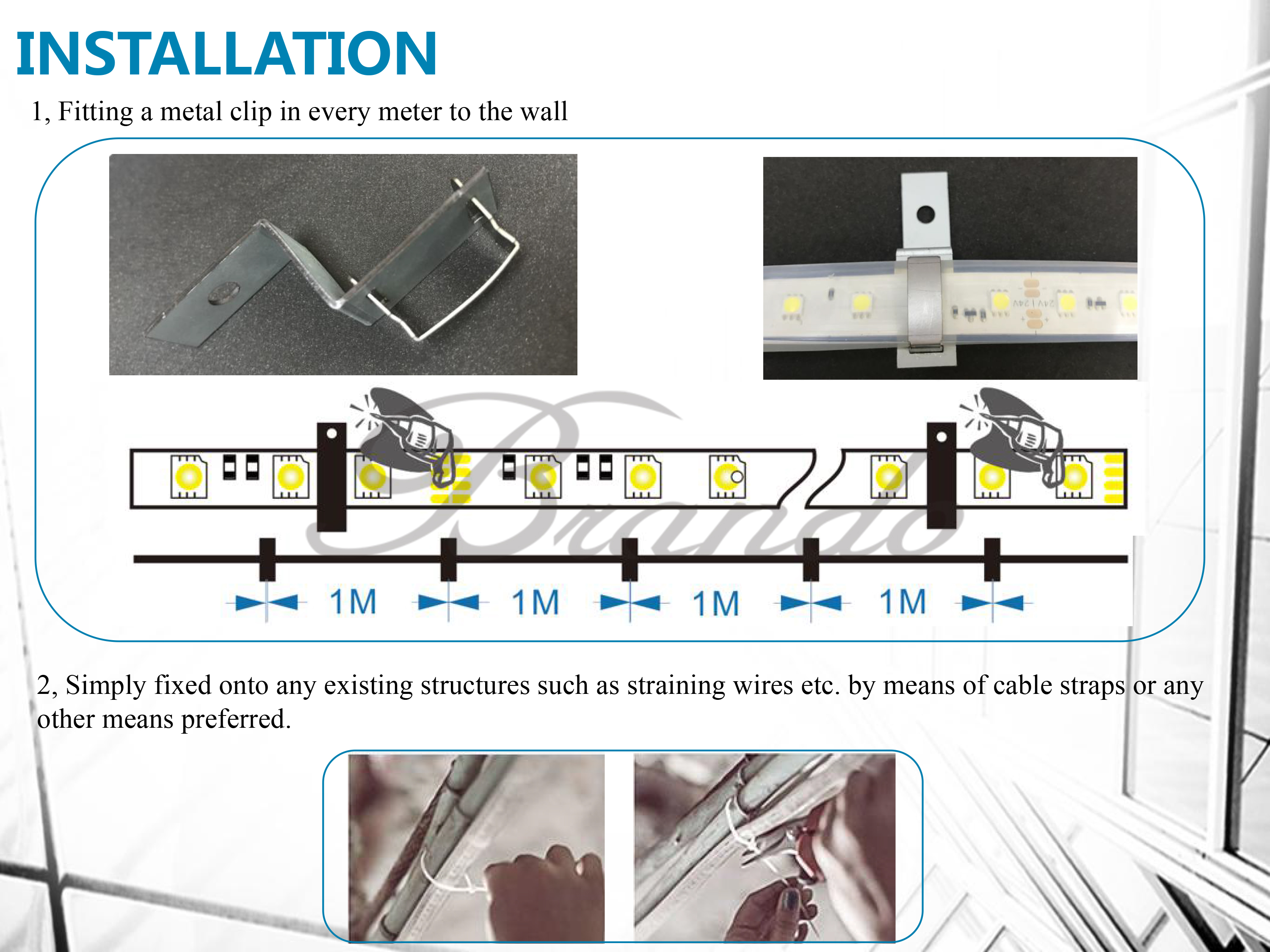

Conventional lighting requires separate power and a wired connection to every lamp, needing the expertise of electricians. This becomes labour-intensive and costly when running many meters of lighting. The BRANDO LED Strip Lighting plugs into an existing power source using a power supply which then connects to one end of the LED strip. A single power supply will light a 20 meter LED section. To extend beyond 20 meters, just add another power supply at the other end and connect the next section of LED strip – it's that simple.

Maintenance-free. Easy to repair.

Damage to lighting through routine underground activities happens. When a conventional lamp is damaged, it results in loss of illumination over many meters – making the affected area a safety hazard until repaired by a qualified electrician. Should a section of the BRANDO strip light be damaged, only this section loses light. The remaining portion of the strip continues to provide illumination – allowing for a safer environment. Additionally, damaged sections can be replaced in 8" strips – making it a quick and cost-effective fix.

• Intelligent temperature management, sensors monitor LED temperature and if safe parameters are exceeded the affected LED’s are automatically dimmed until safe temperatures are restored.

• Intelligent voltage surge management, restorable resistors limit overcurrent and overvoltage situations.

• AC to DC convertors, miniature voltage convertors.

• Short circuit protection, in the case of short circuit the power is isolated until the circuit is normalized.

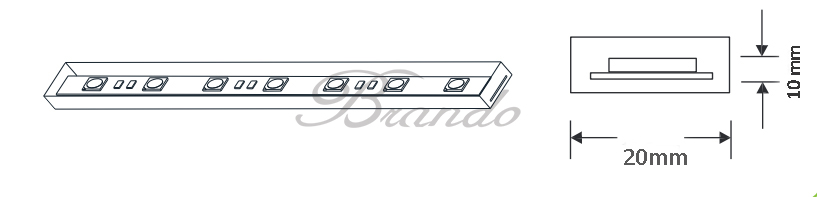

Dimension: 10000mm(length) *20mm(width) *10mm(height)

TECHNICAL PARAMETERS:

| Part Number |

BO-SL60-36V(A) |

| LED Chip |

Epistar |

| LED configuration |

72 LED's spaced evenly over a metre length |

| Range fed from both sides |

40 metres |

| Recommended fixing height |

5 - 6 Metres |

| IP Rating |

68 |

| Power Consumption per LED |

0.25 Watts |

| Power Consumption per Metre |

15 Watts |

| Colour Rendering Index CRI |

> 80 |

| Colour temperature |

10000 Kelvin |

| Luminous Efficacy |

80 Lumens / Watt |

| Voltage on lighting VDC |

36 VDC |

| Supply voltage for power controllers VAC |

85 - 265 VAC |

| Light maintenance |

15%-20% Drop over 4 years |

| Lifespan |

5 Years + |

| Warranty Lighting |

3 Years |

| Outer covering |

Food grade silicone |

| Dimensions |

10000mm(length) *20mm(width) *10mm(height) |

| Tensile strength |

+-50KG |

| Operating temperature |

-40℃ to 120℃ |

| Protection |

Short Circuit

Over Voltage

Over temperature

Over Current |

| |

| |

| |